| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : JJRS

MOQ : 1set

Supply Ability : 10-12 set/year

Delivery Time : 7~10 months

Packaging Details : wooden box; plastic package

Material : Cold Rolling Coil, Hot Rolling Acid Pickling Coil

Thickness : 0.6~1.2mm

Width : 550mm

Annual Output : 150,000 ton

Type : continuous

Coating : Galvanizing, Painting, Plating, Hot dip galvanizing, zinc coat

After-sales service provided : Engineers available to service manchinery overseas, field installation, online support

Name : Continuous Galvanizing Line

Production mode : double/single work line

Price : USD$1,000,000~USD10,000,000

Hot Dip Galvanizing (Aluminizing) Technology --- JJRS-Sendzimir

Hot dip galvanizing galvanizing Line 0.12~0.8mm*1300mm 150,000TPY

JJRS assembles excellent technology research team, high qualified management personnel, perfect management system and powerful engineering design and complete project capability. As an integrated solution provider, we are willing to provide iron and steel enterprises of all over the world with highest quality products and services, from general engineering contracting, integrated production lines, to single equipment, even components and spare parts. JJRS owns a stable user group both at home and abroad; all the contracted engineering projects are highly praised by end users bringing us fruitful success and good reputation. We are promoting actively metallurgical equipments to international market, establishing good trade cooperation relationship with several multinational companies. Our products are exported to Indonesia, Uzbekistan, Russia, Southeast Asia, Middle Asia and other countries and regions.

Hot-dip galvanizing provides a number of benefits to the steel it protects. The metallurgically-bonded zinc-iron alloy layers not only create a barrier between the steel and the environment, but also cathodically protect the steel. The cathodic protection offered by zinc means the galvanized coating sacrifices itself to protect the underlying base steel from corrosion.

The tightly adhered coating, which has bond strength of around 3,600 psi, is also extremely abrasion-resistant, as the intermetallic layers are harder than the base steel (Figure 2). However, even if the coating is damaged, zincs sacrificial action will protect exposed steel up to ¼ inch away.

In addition to the cathodic protection offered by hot-dip galvanizing, there are a few other characteristics of the coating which provide longevity. First, reaction in the galvanizing kettle is a diffusion process, which means the coating grows perpendicular to the surface, ensuring all corners and edges have at least equal thickness to flat surfaces. Furthermore, the complete immersion in the zinc bath provides total coverage of the steel, including the interior of hollow structures.

Technology Patent of " JJRS-Sendzimir"

The launch of " JJRS-Sendzimir" depends on a number of technology patents innovated by ourselves.

| Name | Valued Hot dip galvanizing Line |

| Application | Building Material |

| Width | 1300mm |

| Thickness | 0.12mm-0.8mm |

| Capacity | 150,000t/year |

| Zinc Coating | 30-300g/m2 |

| Component | entry looper etc. |

| Keyword | Valued Hot dip galvanizing Line |

| Type | Continuous |

| Process | Hot dip |

| Coil Material | steel metal ss cs |

| Material | Hot rolled coil, cold rolled coil |

|

|

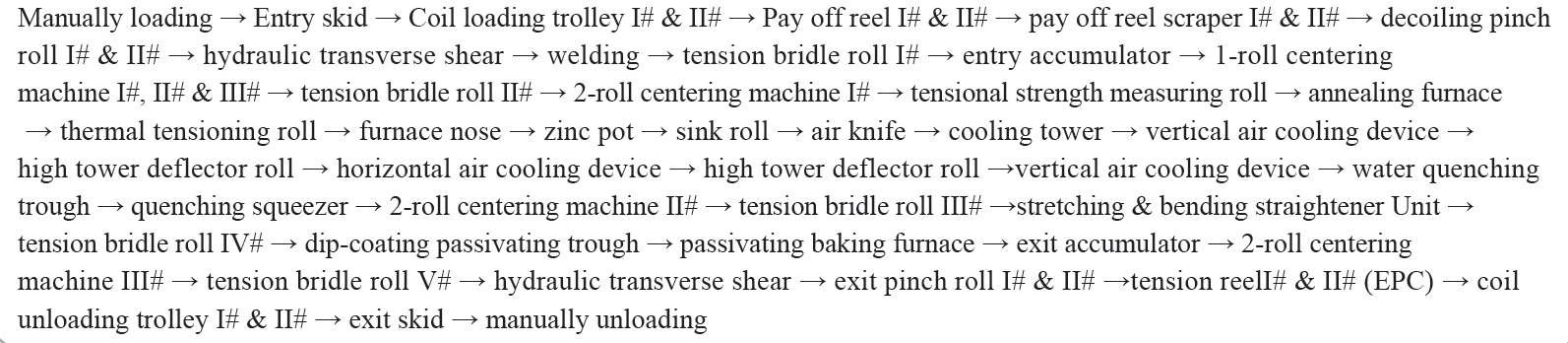

Automatic Turnkey Hot Dip Galvanizing Plant 0.12mm 0.8mm 1300mm 150000TPY Images |